Catalysts

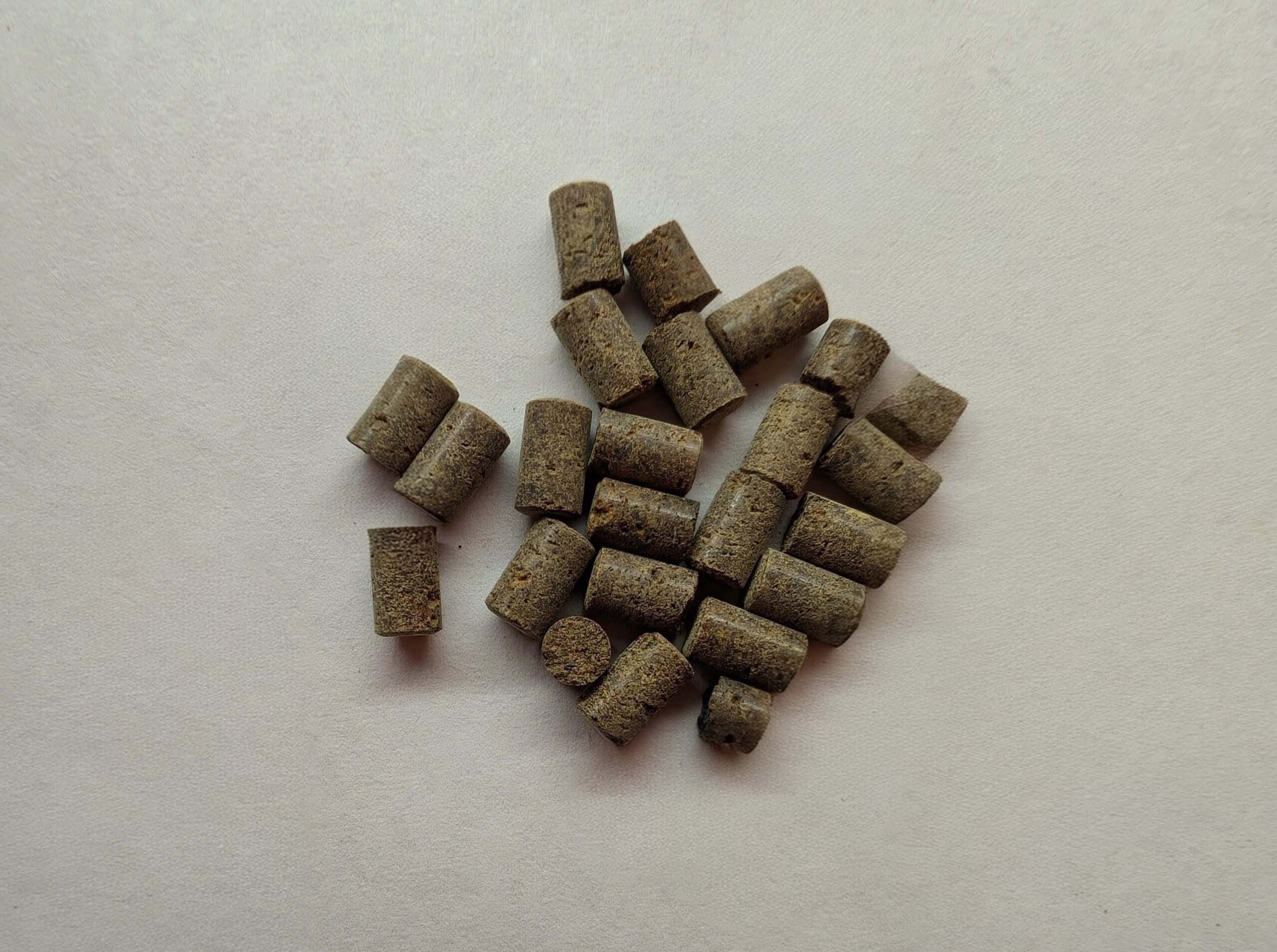

Hydrocarbon Reforming, Ammonia Cracking, and Water Gas Shift reaction catalysts to provide a good mix of high activity and high temperature durability. Available as catalyst pellets or 14-90 mesh catalyst granules to provide a good balance between low pressure-drop and high heat and mass transfer.

Low Temperature Catalyst

Low Temperature Methanol Reformer / Water Gas Shift Catalyst: copper zinc alumina. For catalytic use at 200 – 300°C. Also excellent for H2S sorption from gases, as a protective bed for membranes or any chemical process. Typical grain size = 14-90 mesh; shipping density = 1.34 g/cc.

$1,100/100g or $1,600/200g

Robust, Middle Temperature Reformer, WGS Catalyst

Robust, Middle Temperature Methanol Reformer / Water Gas Shift Catalyst: copper zinc chromia ceria platinum alumina. For use at 250 – 450°C. Typical grain size = 14-90 mesh; shipping density = 1.31 g/cc

$1,900/100g or $2,700/200g

High Temperature WGS Catalyst

Middle Temperature Hydrocarbon Reformer / High temperature Water Gas Shift Catalyst (iron, copper chromia ceria platinum). For use at 400 – 700°C. Excellent for reforming, for Fischer-Tropsch synthesis, and for high temperature water gas shift reactions. Durable in air.

$1,900/100g or $2,700/200g

Iron Oxide Catalyst

Iron Oxide-Based Water Gas Shift and Fisher-Tropsch Catalyst (Iron Oxide, 2% copper, no Pt). A cheaper alternative to the above (no Pt content). For use at 400 – 700°C.

$1,100/100g or $1,600/200g

Nickel Catalyst

Nickel-based catalyst for ammonia cracking at 550-750°C, and for light hydrocarbon reforming at 750°C or higher. Also suitable for removing trace CO from hydrogen through the methane-formation reaction. 14-90 mesh.

$1,300/100g or $1,900/200g

Nickel Platinum Catalyst

Nickel on Alumina catalyst for ammonia cracking at temperatures of 450-650°C modified by SrO2 Ce2O3 and 0.3%Pt, ~301/gmh.

$2,100/100g or $3,400/200g

Hydrogen Removal – Sorbers, Getters, etc.

Three options for hydrogen removal: An organic-based sorber, an oxidation catalyst, and a reversible Pd-Coated metal.

Pd-Organic Hydrogen Sorber

This hydrogen-removal, “getter” is made from DEB, palladium, and buckminsterfullerene. It’s used for irreversible hydrogen removal from air, nitrogen, steam or inert atmospheres, at temperatures from -20 – 50°C. Used in electronic packages, consumer, and industrial products where hydrogen would cause a safety or operational hazard.

$750/5g

Pt Hydrogen Removal Catalysts

% Pt-CeO or Pt-alumina catalysts that remove unwanted H2 by combining it with oxygen. This is best done in the presence of air but the CeO version also works in nitrogen or inert gases. Uncoated catalyst works at 20 – 600°C. Teflon coated catalyst works to -5°C.

Pt-CeO: $950/5g, PtAl2O3: $700/5g

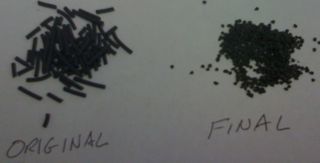

Pd-Coated Niobium Screws and Pellets

Pd-coated niobium screws (4/40 thread by 1/4″ long). Used for reversible hydrogen removal from inert gases, e.g. in space-based electronic packages at 50 – 200°C. Pd coated LaNi5 can be very effective in nickel metal hydride batteries or hydrogen storage. Hydrogen sorption is readily reversible.

$850